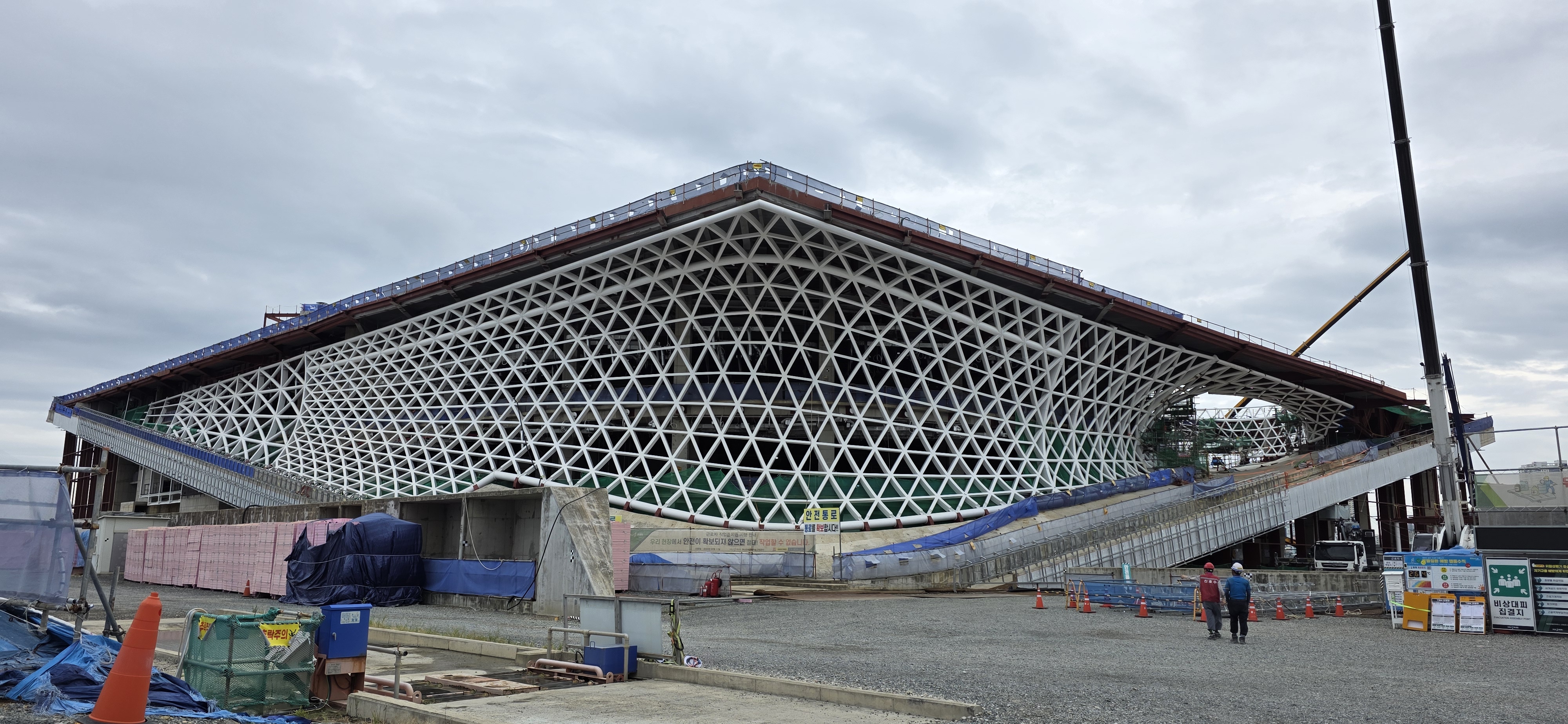

Pusan Opera House

Busan, Korea

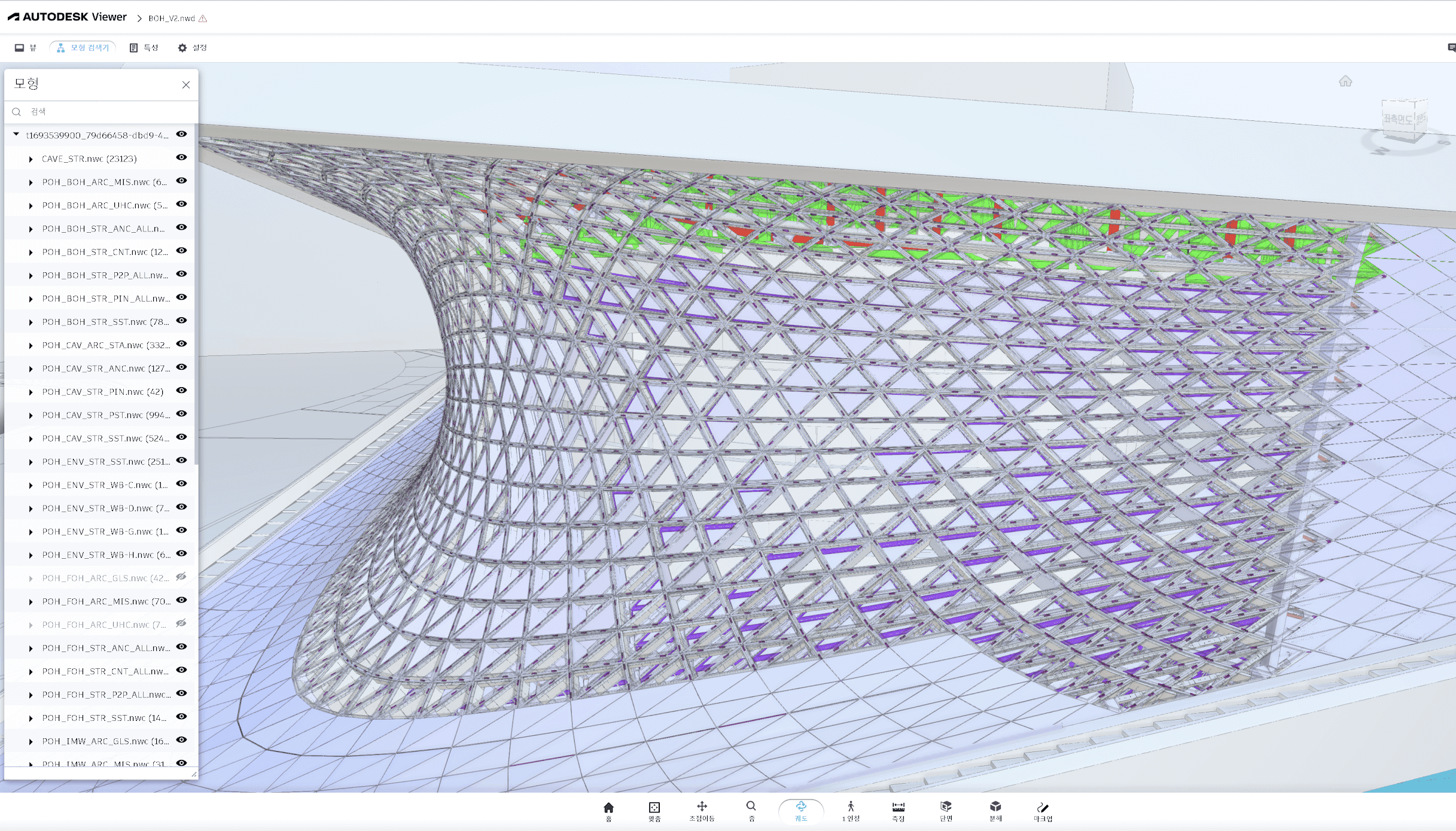

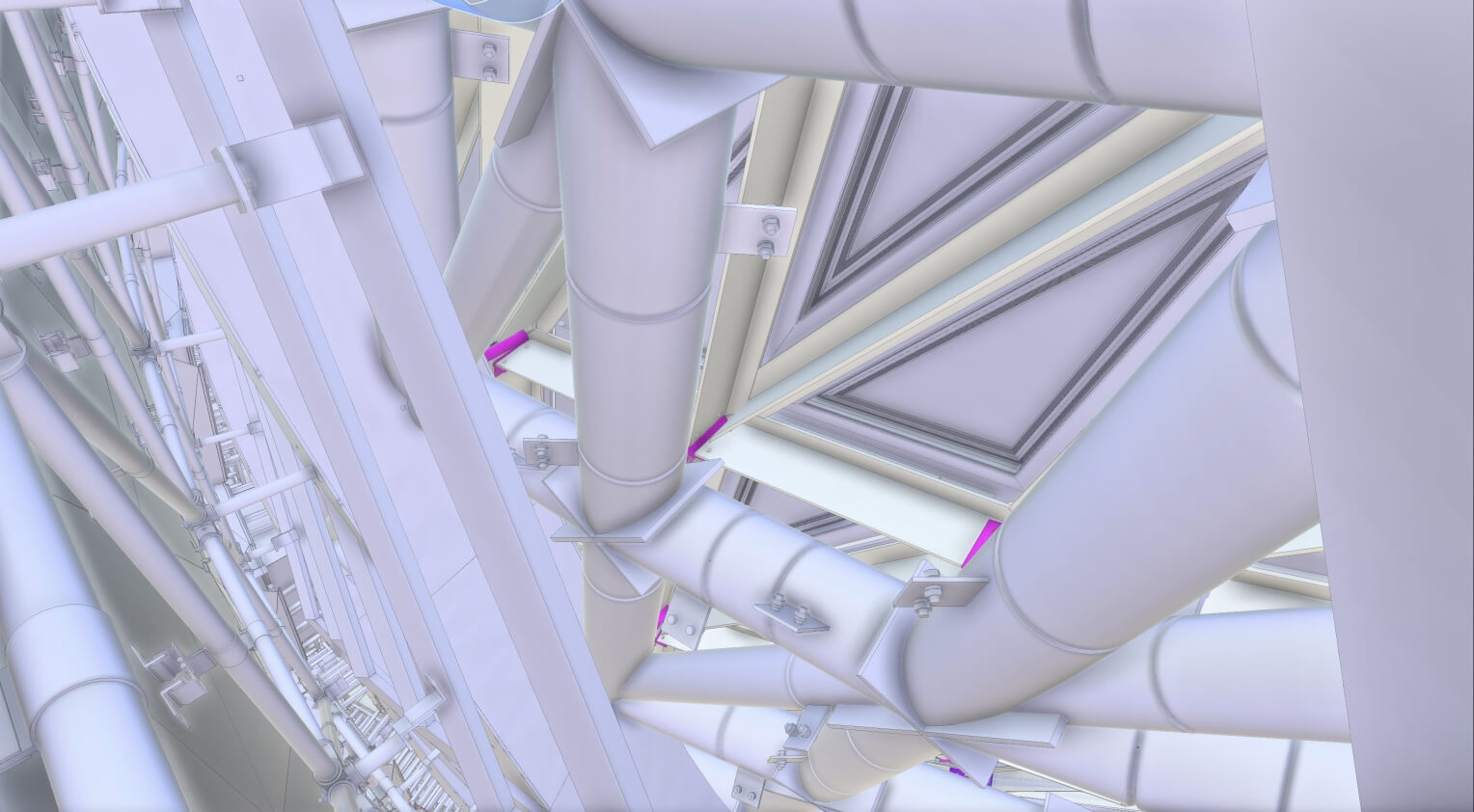

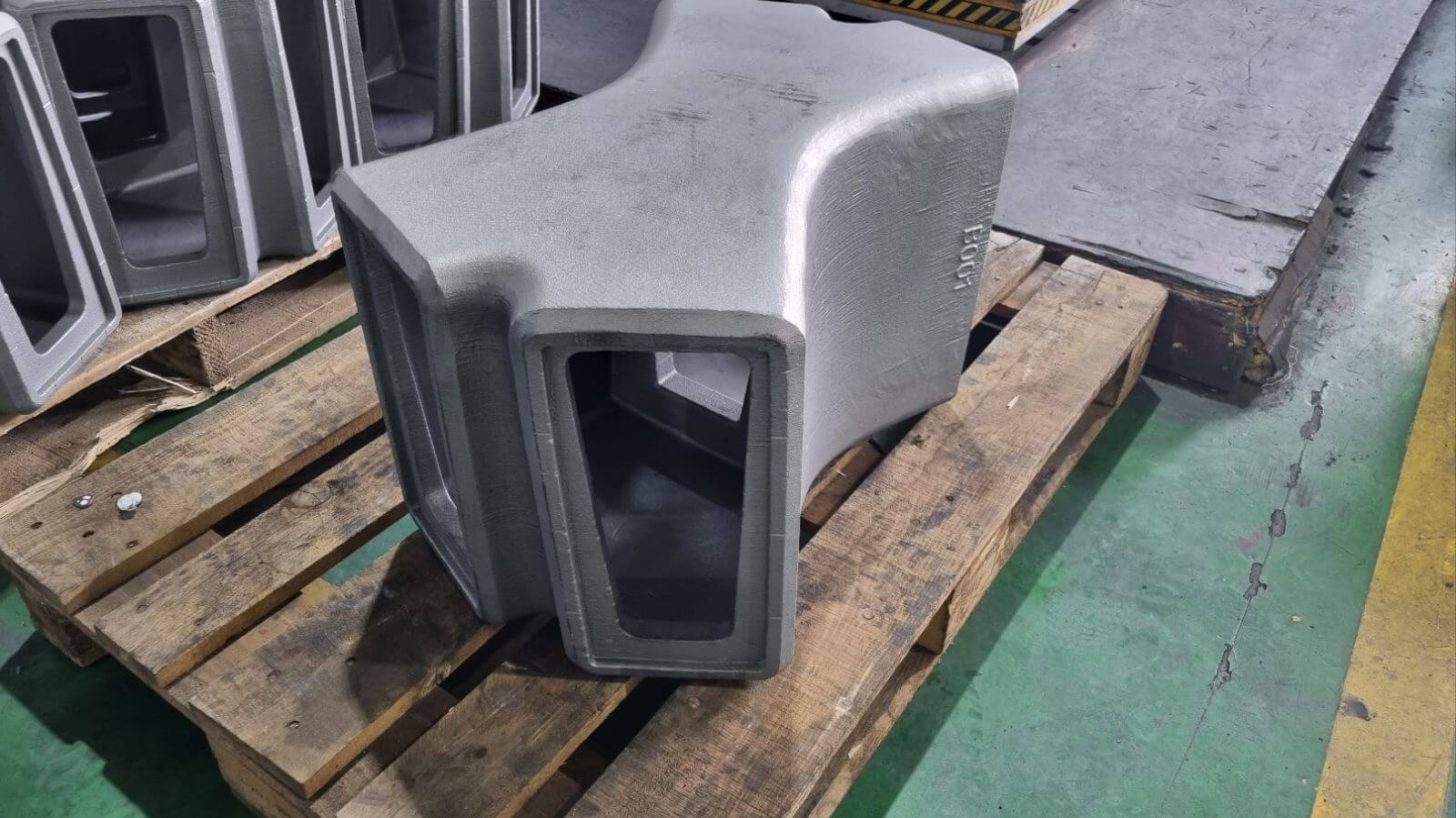

The Pusan Opera House represents one of Korea’s most technically challenging freeform façade projects—defined by twisted, non‑typical steel geometries that demanded extreme precision during construction.

Metal Morph was commissioned by the general contractor to provide comprehensive construction consulting for the complex façade system.

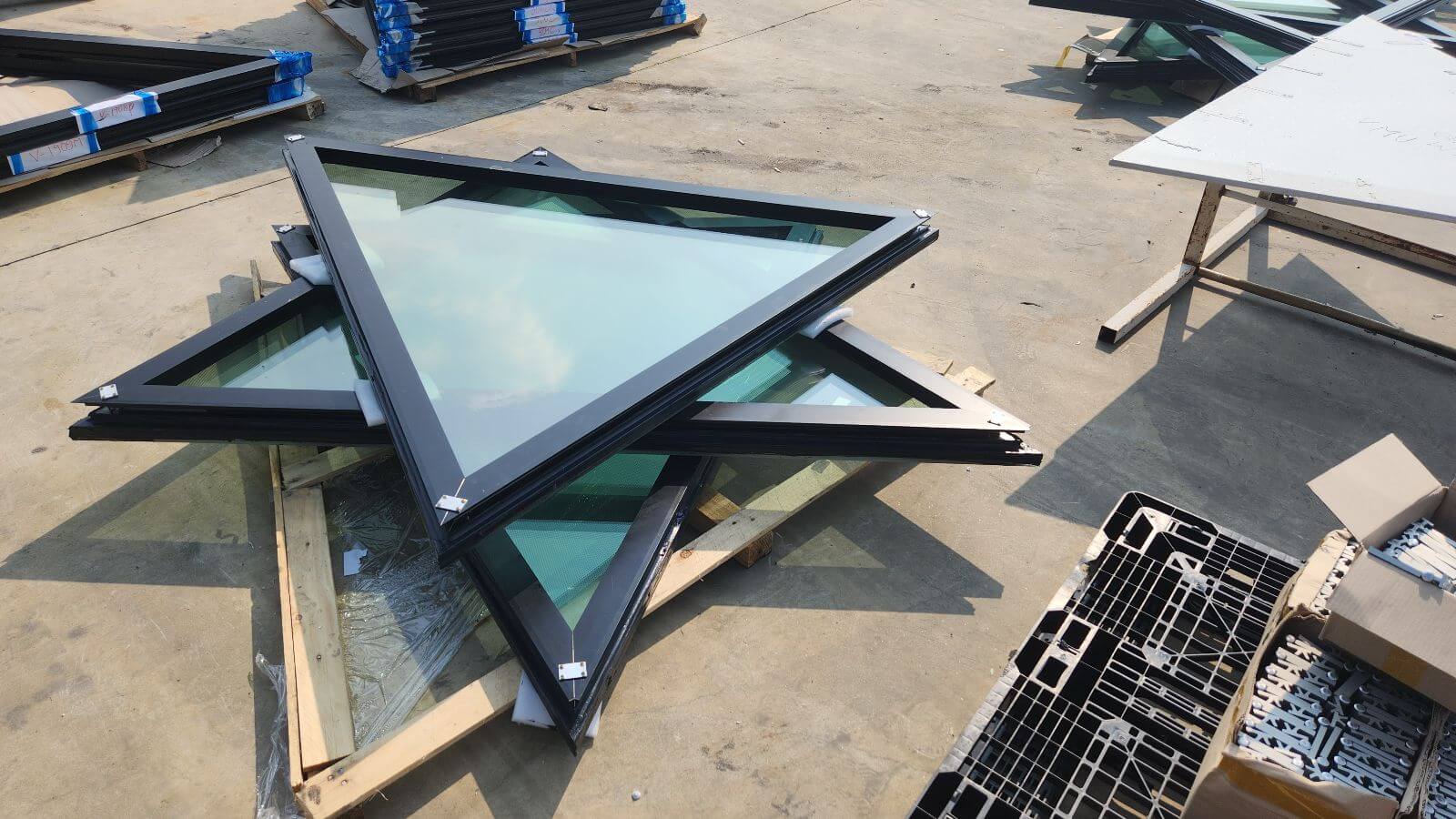

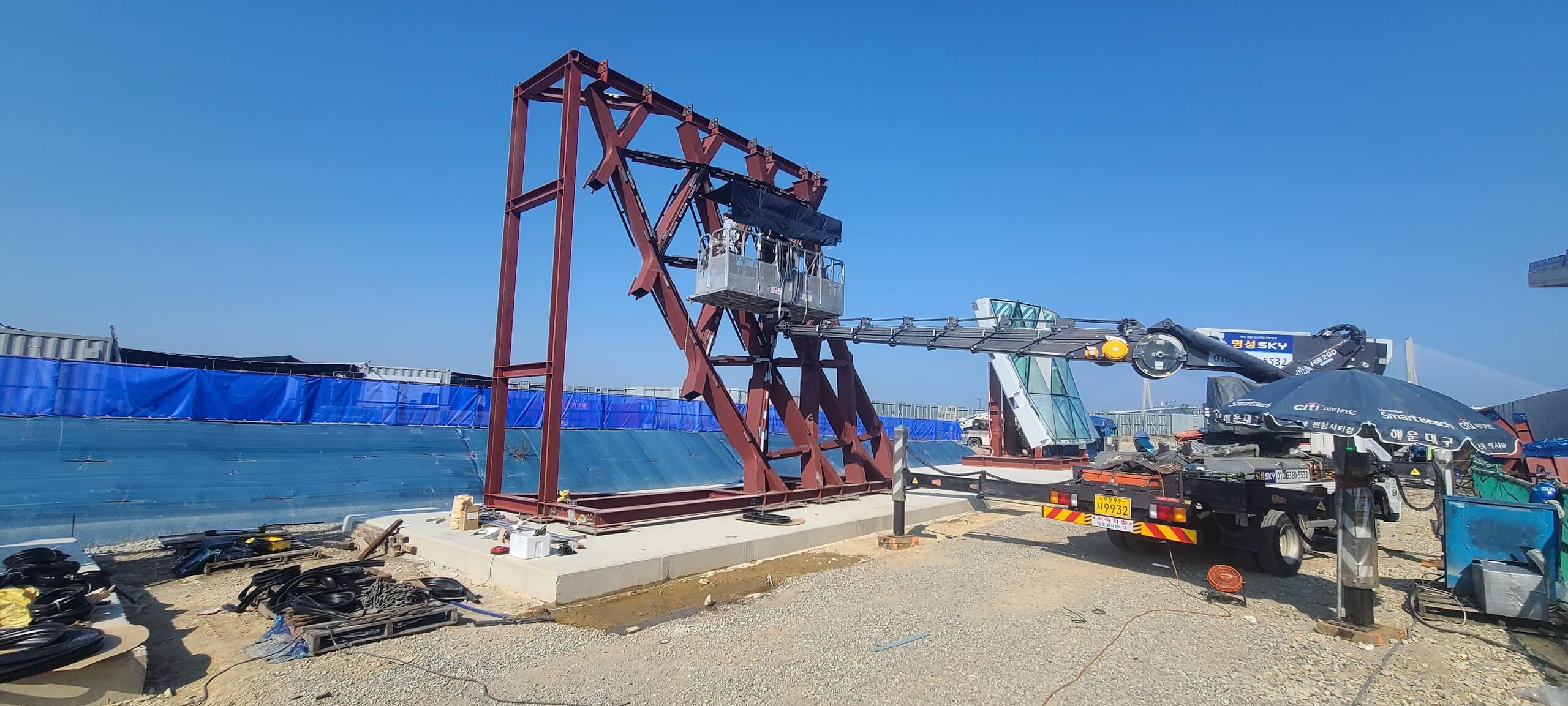

Our scope included detailed design development, structural verification, full‑scale mock‑up fabrication, and installation methodology consulting to ensure that the architect’s design intent could be realized safely and accurately on site.

Using parametric modeling and digital fabrication simulations, we optimized the twisted built‑up steel components for manufacturability and tolerance control.

Through 3D scanning and digital alignment, we validated each fabricated element against the actual site geometry, achieving millimeter‑level accuracy in installation.

This project illustrates Metal Morph’s role as a technical bridge between design and construction, delivering solutions that turn architectural ambition into executable precision.