Technology Built to Be Constructed

Freeform facades engineered for fabrication and installation.

Our Technology Philosophy

Freeform architecture fails

when geometry is not engineered to be built.

Metal Morph engineers freeform facades as a single system — from geometry to installation.

Technology, for us, is not complexity — it is responsibility.

The Metal Morph Approach

A continuous workflow — built for clarity, control, and repeatability.

Geometry Definition

Define geometry not as form, but as buildable intent.

Engineering Control

Control geometry through structure and tolerances.

Fabrication Logic

Translate geometry into repeatable fabrication data.

Installation Precision

Take responsibility for geometry all the way to site.

This is not a linear process — it is a continuous system of control from design to site.

Why Aluminum Sheets?

Not because it is easy —

but because it is controllable, repeatable, and scalable.

Freeform facades are often driven by visual ambition. But not all materials respond well to precision, tolerance, and long-term performance.

Aluminum sheets offer a rare balance — formability, weight efficiency, durability, and control at scale.

- 01Controlled FormabilityAluminum can be shaped precisely without sacrificing tolerance or repeatability.

- 02Lightweight PerformanceReduced structural demand enables efficient systems without compromising geometry.

- 03Scalable ReliabilityFrom prototypes to large-scale production, aluminum supports consistency and long-term reliability.

Technology is not about using exotic materials. It is about choosing the material you can fully control.

This philosophy led us to develop a dedicated system — MM SURF D3.

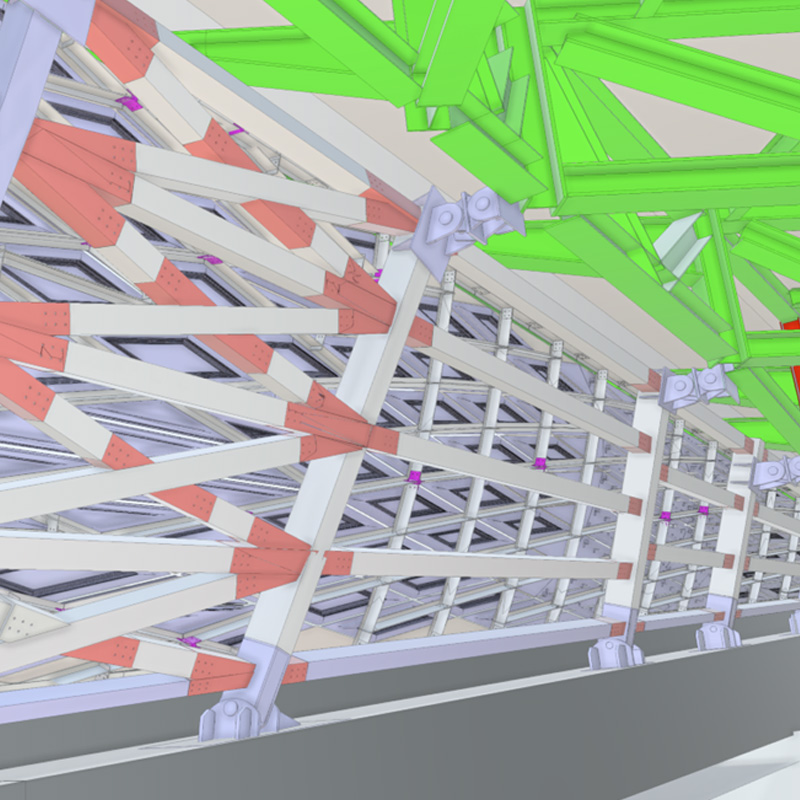

MM SURF D3 SYSTEM

Developed to ensure freeform designs are not just expressive, but buildable, repeatable, and installable at scale.