Angang KTX Station

Gyeongju, Korea

We got the call: “It can’t be installed.”

Our answer? Challenge accepted.

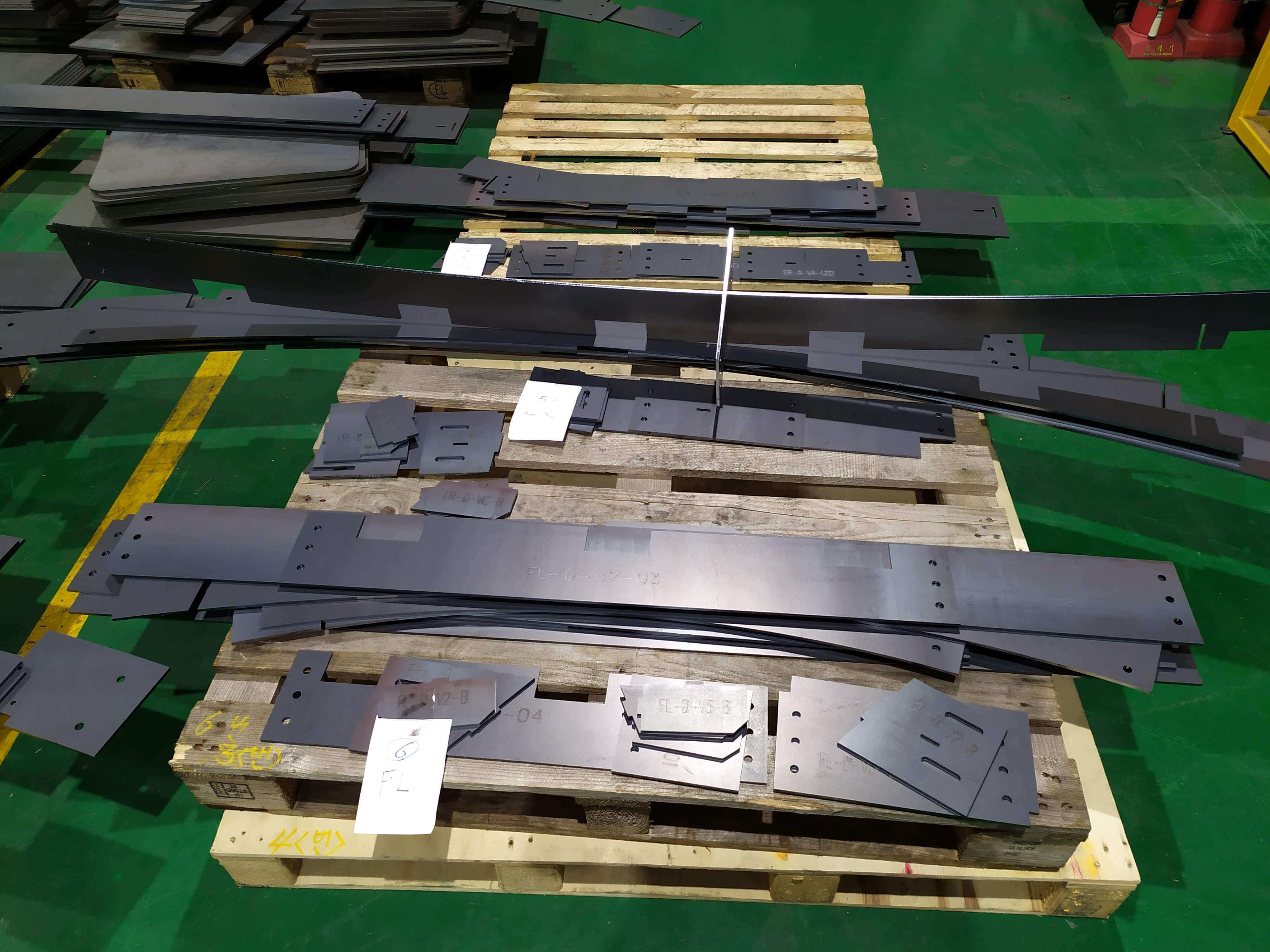

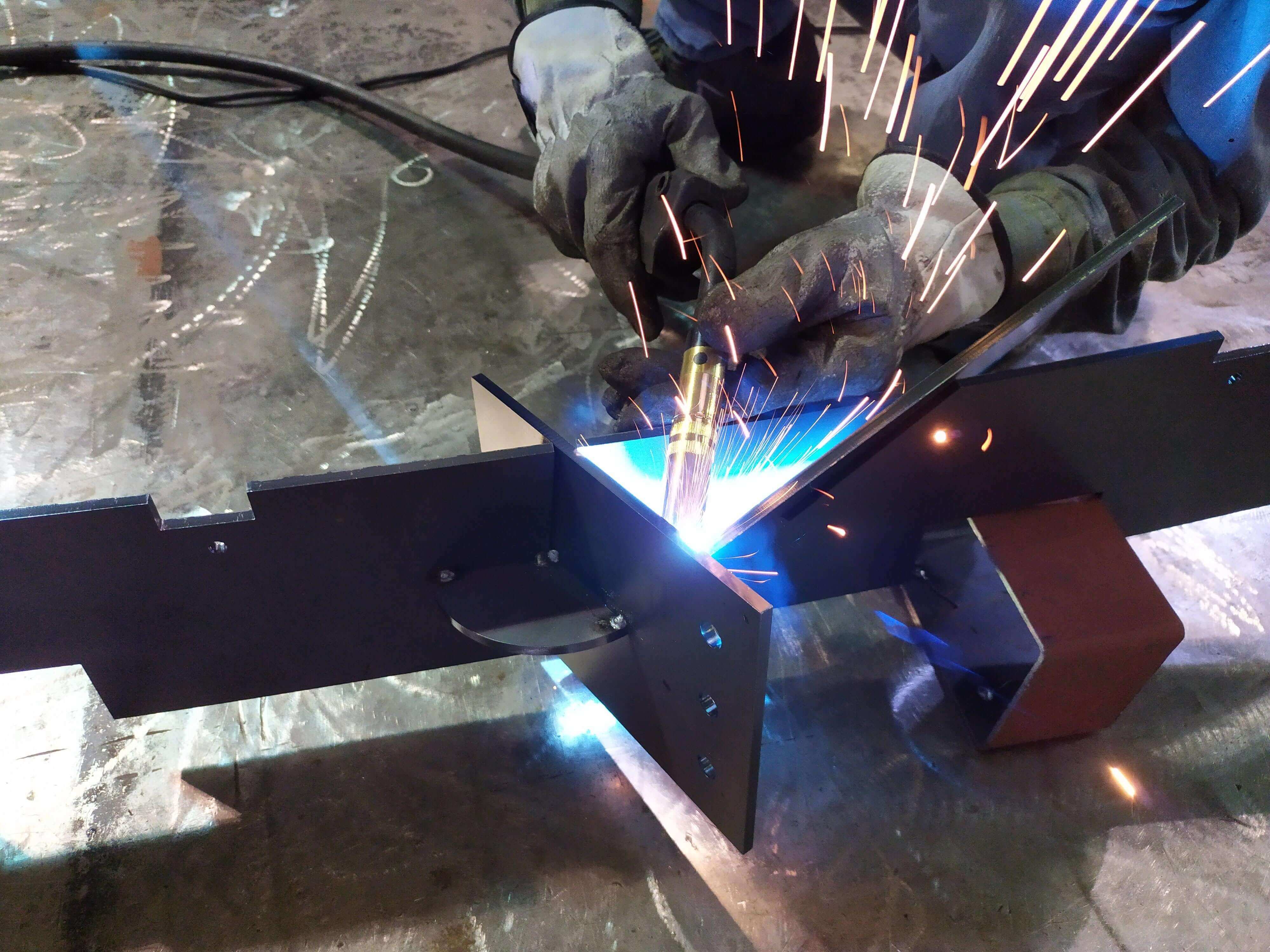

Inspired by the graceful curved eaves of traditional Korean Hanok, the Angang KTX Station façade was designed with smooth, organic corners. But once construction began, the team discovered the curves couldn’t be built on site using conventional methods. Like many projects in Korea, construction had started before the detailed design was complete — and for complex geometry like this, that approach simply didn’t work.

So, we went digital. Using precision 3D scanning, Rhino, and Grasshopper, we rebuilt the entire façade as a fabrication‑ready digital model, automatically generating shop drawings and structural data. By comparing our model against the actual site scans, we detected issues early — before they became costly mistakes.

With tight budget constraints, we performed structural optimization to design a lightweight, modular frame that could be easily reinforced on site. Each curved aluminum panel was press‑formed using custom molds, heat‑shaped, cooled, and then scanned again to ensure perfect curvature and alignment. Once the frames and panels were matched, installation was seamless — precise, efficient, and on time.

Could this have been done without digital design? Maybe — with endless time and money. But Metal Morph believes in working smarter, not harder. This project proves how digital precision turns the impossible into reality.